The following extract is from "Locomotives of Australia" by Leon Oberg (Kangaroo Press 1996). Many thanks to Roger Gibbons for bringing attention to this fascinating article. Robin advises that One X Class and five "XA" Class are preserved, the latter appears to be a slightly modified version.

|

| A collection of X and 'CA locomotives at Forrestfield locomotive depot on 15 July 1979 showing their unusual 2-D~2 wheel arrangement to full advantage. At left is No. Xl021 and at right No. XAl415 showing the communication nose doors. (Peter Wans) |

Quality British steam locomotive builder, Beyer-Peacock & Co teamed up with Metropolitan Vickers Electrical Co Ltd to supply forty-eight unusual 2-Do-2 779 kW X-class diesel-electric locomotives for Western Australian Govemment Railways from 1954.

This was the largest single order for diesel motive power yet placed by an Australian railway and the units entered service between March 1954 and 1956.

The 2-Do-2 wheel arrangement was something akin to steam locomotive practice in that the leading four-wheel bogie 'steered' the unit through the curves as the eight driving wheels, attached to the rigid main frame, provided the traction. But this arrangement caused rough riding and, in addition, just half of the locomotive's all-up 80.2 tonnes weight was available for adhesion which contributed to wheelslip. Like many early diesel locomotives, the X-class was fitted with a marine-type diesel engine, this one being a Crossley eight-cylinder HSTVee-type used in submarines. In locomotive service it reportedly 'oiled up badly'.

The locomotive had some advantages. Because of its relative light weight spread over so many wheels, it was able to tread the entire WAGR network where some lines were laid with rail as light as 20 kg/metre.

When enough were available to assume control of the state's top express runs including the Westland, Albany Express and Kalgoorlie Express, the X-class decimated steam-era timetables for these trains. For instance, the previous seventeen-hour Kalgoorlie Express schedule was reduced by as much as four hours!

Whilst under construction, the final sixteen locomotives were wired for multiple-unit control and fitted with 'intercommunication' doors at each end. Accordingly, these became known as the XA-class. In later years, WAGR decided to wire ten of the original X-class for multiple-unit control but as these were not provided with the endaccess doors, they became the XB-class.

Despite alleged faults, these well-proportioned dual-cab locomotives continued to tread the system's 1067 mm gauge network until late 1972 when two units in poor condition, Nos. 1015 and 1029, were withdrawn to supply parts for sister locomotives. On 17 November 1976, both were written off.

Withdrawals started in eamest from the early 1960s with the closure of many light branch lines and the last 'X' in service was No. 1017, retired in January 1986 and the last 'XE' running, No.1017 was withdrawn on 17 October 1986. With 2 623 473 km behind it No.1017 had the eventual honour of running the furthest distance of any X/XA/XB.

Of the remaining XAs, some were equipped with Westinghouse airbrake equipment (Westrail gradually moved over to this universal system after having employed the vacuum type of braking since its inception) and these survivors could be found working Perth suburban passenger rolling stock until the last unit, No. XA1402, made its last trip for Westrail at the head of the 17:10 Perth-Armadale 'local' on 30 March 1988. The following day, No. XA1402 worked a freight train from Forrestfield to Midland, thus closing the chapter on the class for the WAGR.

One X-class and five XA units have been preserved. Classleader, Nos. X1001 and XA1402 reside at the Bassendean Rail Transport Museum; No. XA1401 was sold to a group of Hotham Valley Tourist Railway members for likely restoration to running order; No. XA1405 was acquired by the ARHS; No. XA1411 now belongs to a Hotham Valley Tourist Railway member; while No. XA1415 resides in a Narrogin park.

SPECIFICATIONS:

| Gauge: 1067mm | Imperial | Metric |

| Traction Horse Power: | 1045 | 779kw |

| Starting Tradive Effort: | 26 000 lb. | 116 kN |

| Continual Tractive Effort: | 12 000 lb. | 53 kN |

| Total Weight: | 78.6 t. | 80.2t |

| X Class: | 1001 - 1032 |

| XA Class: | l40l - 1416 |

| XB Class: | 1004, 1006, 1008, 1017, 1018, 1020, 1022, 1024, 1027 and 1032 |

Nic Doncaster advises that Hotham Valley Tourist Railway, XA1401 is now the sole operating Crossley.

Australian Railway Historical Society owns 1001 and 1402, but neither locomotives are operational due to life expired batteries.

However, Nicholas Pusenjak of Perth, Western Australia, has subsequently written that one of the preserved Metrovicks in Western Australia has had a run on the main line in the year 2000.

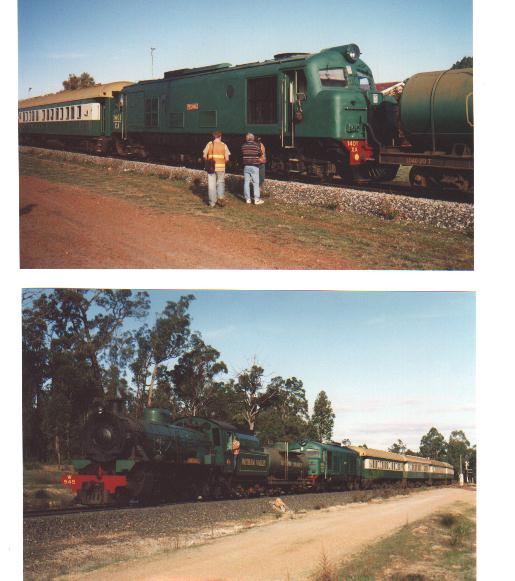

XA 1401 double headed with a W class 4-8-2 from Pinjarra to Collie on 27th May 2000 and ran like a Swiss watch. For those fortunate enough to know these locos in their heyday, it was fantastic to hear that Crossley diesel engine again and feel the whole loco vibrating when at idle when the train stopped.

The smoke problem (much to the photographer's disppointment) seems to have been cured with developments in piston ring technology, but it was still great to see and hear this loco in action. Two of Nick's pictures of the day's events follow :-

The following article was originally published in "The Partyline", the in-house magazine of Steamtown, South Australia, written by Nic Doncaster based on a Manuscript written and made available by Jim Bisdee. Reproduceed here by kind permission of the author.

The Crossley Engine

The early efforts towards dieselisation had been the theme of several articles in "The Partyline", with most of the emphasis being placed on the WAGR "X" class and CR "NSU" class units; mainly because of the earlier dealings Steamtown had had with these classes.

The CR had a well established tradition of buying only known or proven design for all of its motive power, And with only one or two exceptions, this policy led them to run one of the most successful motive power fleets in the country. The NSU was, in its day, an "unusual" machine in Australia, but its power plant, a Sulzer LDA, had a well proven track record in Europe. Indeed, when it came to the first days of dieselisation , the respective states and private operators all looked to the experienced builders for their new power: Whether they were the locally assembled English or American locomotives, or ones they built themselves with components sourced from a known manufacturer. All but one operator chose the "proven design" path, although it would have seemed that due to a variety of factors there was, it seemed, not much choice.

The WAGR tendered out for a locomotive that could run over all of its lines, some being so lightly built that a 10 ton axle load was called for. The units that the WAGR sought had to produce 26,000lb in tractive effort, be fitted with a driving cab at both ends and be able to negotiate curves down to 5 chains radius.

The WAGR received numerous submissions for what would be one of the largest diesel motive power contracts let by an Australian System. Submissions came from Japanese, American, European and British manufacturers, and was eventually won by the fifth cheapest tender, submitted by Metropolitan Vickers (metro-vick) .

In order to comply with the light axle load, a design running on the odd configuration of 2-DO-2, with a "Crossley" HST-Vee8 powering Metro-vick Electrics was submitted. To build the body, Metro-Vick had set up a joint venture with the respected Beyer Peacock in 1947, although the partnership did not get under way for several years as Beyer were still building steam locomotives from a full order book, ironically including the successful "W" class.

Thus, the first failure in the project was the letting of the contract to a company that had never knocked out a diesel locomotive and so began a saga that would plague the WAGR for the next 35 or so years. The second, and perhaps most serious failure in the project was the use of an unknown traction engine.

Although the Crossley Brothers had been building rugged and reliable engines for many years, particularly for marine applications, it had, up to the arrival of the contract for the "X" class units, never built an engine for locomotive ("traction") use. Indeed, at the time Crossleys won the contract, the engine was little more than a pipe dream. though predecessor engines had been successfully and extensively used during World War 2 powering motor torpedo boats. There is nothing to suggest that the HST-Vee series engine was a War surplus item intended for a submarine application, and research has not been able to confirm that these were used in the "K" class submarines despite comments from other authors that the engine was applied in these boats, causing hull failures with their vibrations. Interestingly, it has been noted that the Irish Railways (CIE), through the respected Engineer Bullied, had "heard" through the British Admiralty that the "Crossley unit gave no trouble".(1) The myth of submaritime service also permeated the CIE (1). Literally, at the time of contract being let, the HST Vee was still on the drawing board.

Early on in the project, delays within Crossleys prevented a prototype from being built for several months, which in course delayed testing by the same time frame. Even at this early stage, the WAGR Inspectors at Crossleys Openshaw plant were expressing serious concerns about the designs of the engines, particularly the oil passages, bearing sizes , and as a consequence the type of bearings being fitted. Loyalty to the "respected British" led the Assistant Engineer, C W Clarke, to question the skills and experience of the engineer who delivered this report, even though it highlighted the serious problems with this engine early on. Despite his pleading, the inspector was ignored. As the design and testing progressed (now some four months behind schedule) a second unit was run for testing. This demonstrated a high exhaust temperature, and had high levels of lubricating oil consumption. Further improvements were made and a later prototype was built, with the blower being incorporated as part of the engine. This unit also used excessive lubricating oil. Problems were also detected with the fuel injection system, but Crossley persisted with its own design, despite concern from the Inspector. A proposal to use well proven CAV injection equipment was rejected. But following the expiration of Warranty, the WAGR retrofitted CAV systems to the engine.

The first set of frames were finished by the Crossleys had completed the testing of its engine and assembled a production unit. This was tested in January 1953 and again used excessive lubricating oil. This was a turn around of some 25 months from design to production construction for the HST-Vee series engine. With works testing undertaken in last 1953, reports continued to confirm earlier suspicions regarding the HST design. Even during testing in the body of 1001, concerns were raised as the assembled locomotive suffered whole body vibration, particularly when running in the 500 to 625 rpm range. The test engineers report continued to reflect the inadequacy of this design, and in their reports raised issue as to the effect of this vibration over frames, bogies, bearings and even the crews. The issue of high lubricating oil temperature was raised.

X1001, "Yalagonga" was shipped to WA in January 1954 and was trialed by the WAGR in March. Despite the fanfare of the launching of X1001 and X1002 in May 1954, the thrill of this new machine was short lived. Indeed, even before their launch the class were subject of concern for the Engine Drivers, Firemans and Cleaners Union, let alone the WAGR, with vibration and oil consumption problems already surfacing.

However, less than two weeks after the introduction of the Crossley powered units, the faults gradually became apparent. With only some 5481 miles on the clock, 1001 cracked a cylinder head, and not to be outdone,1003 followed less than 6 days later with a mere 3230 miles and eight cracked heads. The manufacturer responded with a new design of head as it had "anticipated the problem"! Interestingly in their marine guise the units ran iron pistons and heads, but to reduce weight in its traction form (to meet the 10 tonne axle load required in the contract) these had been replaced with aluminium. This attitude to saving weight also led to the manufacture of hollow shafts, and an engine block with much "meat" removed to reduce mass, and as a result, less structural strength.

The new heads lasted 10 weeks in service, despite the WAGR indicating its preference for cast iron: Crossley would later supply cast iron heads. Within a few months of entering service, X1005 broke her crankshaft as the crew tried to start her, not realising there was low bearing pressure for lubricating oil. The Crossleys were hand primed, not unlike the CR Sulzers. Further, the bearings were confirmed to be underfed for oil (as noted by the Inspecting Engineer earlier in the project), whereas other designs of engine were oversupplied. The engine also failed to have any form of low oil pressure warning device fitted.

As more of the class entered service, the implementation of the dieselisation of the WAGR fell further and further behind, delivery itself taking five and a half years over the contracted four. As failures mounted, so did a motive power crisis. More and more of the "X" class were lining up for repair with fewer and fewer spairs available to complete the repairs. At one stage the fleet had an availability of 65%, way below the 84% for steam.

By March 1956, another problem came to light: that of a flawed oil supply. Tests confirmed that, in certain circumstances, the pistons were deficient in oil, caused by air entering into the lubricating system. Modifications were made to the sumps of the engines thus eliminating this problem.

Whilst the WAGR were having problems with their Crossley units the Irish Railways (CIE) and British Railways were in the same boat, having bought the same engine to power one group each of their locomotives. The CIE advised the same problems: shattered pistons, cracked heads, oil deficient operation, excessive liner wear, and big end bearing problems, not to mention broken fuel and water lines and radiator failures, and from all accounts the BR experience was no better. Most of these problems were expressed as concerns by the Resident Engineer at Crossleys early in the project. And as the pistons did not last long in service a newer design of piston, made of cast iron was eventually supplied by Crossleys. The Irish units were fitted with iron pistons from Day One and they had failures! The new pistons ended a four year saga of piston failure, and improved the availability of the locomotive.

The next major issue to surface was that of ring failure scuffing and failure. This produced a high level of iron in the lubricating oil of the engine, and after testing some 16 units were withdrawn from service. Crossleys forwarded several sets of rings, which gave the WAGR engineers the impression that even the manufacturer were unsure of just what the "genuine" part was. In the end the ring problem would take some 25 years to resolve.

The CIE were not as tolerant as the WAGR with their dealings with the Crossley plant, due to their reliability, and re-engined their units with GM-645-E series plants early in their life. The BR scrapped the greater portion of theirs after 10 years. A Royal Commission investigated the possibility of repowering the"X" in 1958. This was rejected due to a combination of factors, including the expense (the WAGR could have purchased 15 new locomotives for the price of repowering the "X" fleet, which would have not only increased the available fleet but would have assisted the Commission in ridding itself of this beast). During this same Commission, Clark was chided for his faith in the British. The report noted that "Clark and the Commission seemed to have been imbued with the idea that railway work could always be done better outside of Australia than within"......"facts do not support this". Commissioner Smith also noted that the 4th lowest tender, from the Birmingham Railway and Carriage Company (who were to build the CR "NSU") using a Paxman engine (a brand in service with the "Y" class shunter) would have been a better purchase with a savings of some £240,000. He noted that the original Tender Committee had stated in its report that "with an order of 48 engines, no risks should be taken".

Although more likely an age problem, leaks later developed in the engines cylinder liner, as it became increasingly difficult for the liners to be kept tight in the block. The WAGR made most of the spares for the "X" class, at one stage at less than half the cost of genuines. This continued up until 1983 and helped overcome the terribly slow service from Crossleys:indeed they later went broke.

Despite their obvious shortcomings, failures and subsequent (650) modifications, the "X" reduced the cost of train operation by 100 pence to 83 pence per train mile. This was substantially higher than the NSU (57p) and the GM (45p), and as a result of the Royal Commission, the WAGR seemed to have learnt its lesson regarding proven engine design.

Additional Information:

The Irish experience with dieselisation was a little more dramatic, in terms of practice changes, than that of the WAGR. With the introduction of the "A" classes to service the CIE immediately introduced one man crewing. If a steam engine was worked out by a crew, the fireman was paid to work home in the train, not ride in the cab of the locomotive.!

Renehan, in his article, also notes the notorious unreliability of the Crossley plant (in this case the ESTVee8 fitted to the smaller C class), in Ireland:

"On the poor perfomance of the C class ..........Bullied attriubted this to the drivers's fears on using notch 10 (full power) on these locos, and risking a failure. There seems to be some truth to this suggestion: here is a story to illistrate this:

Inspector Jerry Whelan was instructing some young drivers on the C class.......on the climb up to Glasnevin Junction, Jerry instructed the driver to put the locomotive into notch 10. Hardly had they gone 100 yards when the engine failed".

Not long after the introduction to service of the "X" class, Crossleys produced a new brochure extoling the virtues of their new HSTV engines. Amongst other comments the brochure notes "copious force feed lubrication", "these engines are of modern design and simple to operate, require a minimum of maintenance", "constructed upon extremely robust lines", "seek to combine the reliability of a steam engine with the economy of the diesel engine".

My favourite paragraph in the brochure:

"These engines are supreme for their very smooth, vibrationless running. There is an absence of mechanically operated inlet and exhaust valves, push rods, rocker levers, cams and side-shafts. Crossley engines have set a very high standard of sweet quiet operation and abscence of vibration, and they are frequently the subject of delighted comment"! One wonders if the typographer accidently read the marine brochure whilst setting the loco one.

References:

Renehan,D: "Crossley diesels of CIE". Journal of the Irish Railway Record Society, Vol 15 pp25-35 and 70-79

Bisdee, J: "Diesels Metropolitan Vickers built", unpublished manuscript 1990

Crossley Brothers Limited: "Crossley Vee and straight line Locomotive Engines", Undated promotional brochure.

Australian weblinks:

Railpage Crossley pages