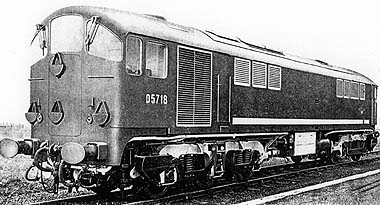

Fig. 1. The AEI 1200hp Co-Bo diesel-electric locomotive

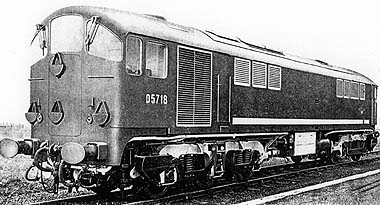

Fig. 1. The AEI 1200hp Co-Bo diesel-electric locomotive

The locomotive (Fig. 1) has two bogies and a cab at each end. The axle load is 19.1/2 tons. The locomotive is driven from the left-hand side of each cab, and up to three locomotives can be operated in multiple.

Locomotives can also be operated in multiple with others which have notch control, such as Brush Traction, Ltd., Type 2, and North British Locomotive Co. Types 1 and 2, fitted with electrical equipment made by General Electric Co. Up to three locomotives can be used in any combination of the above types.

The Crossley two-stroke cycle diesel engine is rated at 1200 hp.

| Gauge | 4ft 8.1/2in. |

| Type | Double bogie |

| Wheel arrangement | Co-Bo or 0-6-4-0 |

| Total weight in working order | 97 tons |

| Length overall | 56ft 7 1/2in. |

| Length over buffer beams | 53ft 0 in. |

| Bogie wheelbase | 12ft 1.1/2in. and 8ft 6in. |

| Total wheelbase | 42ft 7in. |

| Distance between pivot centres | 32ft 4in. |

| Width overall | 9ft 2.1/2in. |

| Height overall | 12ft 8.3/4in. |

| Wheel diameter | 3ft 3.1/2in. |

| Type of bogie | Cast steel with swing bolster |

| Diesel engine | Crossley HSTVee8 |

| Diesel engine output (service) | 1200 hp at 625 r.p.m |

| Maximum tractive effort at rail | 50000 lb |

| One hour tractive effort at rail | 25 650 lb |

| Continuous tractive effort at rail | 22 900 lb at l5.4 mph |

| Maximum service speed | 75 mph |

| Minimum curve radius | 3.1/2 chains (44 chains with gangways coupled) |

| Fuel tank capacity (engine and boiler) |

575 gallons (main) plus 10 gallons (engine service) |

| Lubricating oil capacity | 125 gallons |

| Boiler water tank capacity | 600 gallons |

| Cooling water capacity | 40 gallons (radiator) 100 gallons (engine) 60 gallons (header tank and pipes) Total = 200 gallons |

| Radiator | Serck double-bank type with sectional elements |

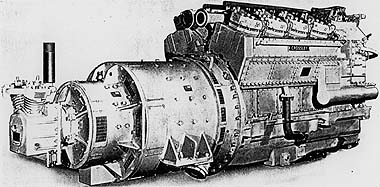

Fig. 2. The AEI 1200hp Co-Bo diesel-electric locomotive

| Eight-cylinder diesel engine | Crossley two-stroke cycle (Fig.2) Type HSTVee8. 1200 hp at 625 r.p.m. Idling speed is 375 r.p.m. |

| Looking on the free end of the engine, the direction of rotation is clockwise; A bank is on the left (right-hand side of the locomotive), B bank is on the right (left-hand side of the locomotive). No. 1 cylinder is at the free end of the engine. |

|

| Cylinder bore and stroke | l0.1/2in. x 13.1/2in |

| Cylinder firing order | lA, lB, 4A. 4B, 2A, 2B, 3A, 3B. |

| Fuel injection equipment | Crossley |

| Type | HCN multi-hole nozzle |

| Pressure at which fuel injector should be set | 2300 lb/in2 |

| Fuel pump type | Crossley port-controlled spill type. |

| Scavenge blower | Three-lobe Roots-type, chain-driven through torque-limiting clutch. |

| Main generator | D.C. self-ventilated, with pressurised inlet, Type TG 4204 eight-pole. Continuous rating 1070/1520 amp, 750/520V at 625 r.p.m. |

| Auxiliary generator | D.C. self-ventilated, Type AG 103AZ, six-pole, continuous rating 62kW, 110V, 400/625 r.p.m. |

| Traction motors (five) | Force ventilated, Type MV 137 BZ, four-pole, continuous rating 330 amp, 475V, l80hp at 510 r.p.m. |

| Traction motor gear ratio | 15/67 single reduction spur teeth. Resilient gear wheel. |

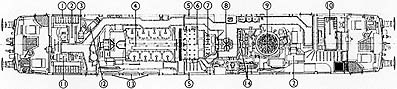

Fig. 3. Auxiliary Equipment

| (1) Engine-cooling equipment | Double-bank radiator panels with Type AY21AW motor-driven fan, nine sections for lubricating oil-cooling water, and nine sections for jacket water. |

| (2) Traction motor blower fans | Two 110V motor-driven Type AY124EV 1400 c.f.m. centrifugal fans. |

| (3) Fuel transfer pump set | Type DY1514B, 110V motor, driving 90 g.p.h. fuel transfer pump and load- regulator servo-pump delivering 17 g.p.h. at 30 lb/in2. |

| (4) Diesel engine | |

| (5) Battery | Forty-eight cells D.P. lead acid Type RSKA 139, 139 ampere-hours, at five-hour discharge rate. |

| (6) Main generator | |

| (7) Auxiliary generator | |

| (8) Air compressor | Worthington Simpson, Type VL79S, single-stage, air-cooled, with displacements of:-

5l.75 c.f.m. at 625 r.p.m. corresponding to 35 c.f.m. free air at 100 lb/in2 3l.0 c.f.m. at 375 r.p.m. corresponding to 21 c.f.m. free air at 100 lb/in2 Cut-in pressure 85 lb/in2 Cut-out pressure 100 lb/in2 |

| (9) Train-heating boiler | Spanner automatic oil-fired boiler capacity 1500 lb steam per hour at 100 lb/in2 |

| (10) Control Cubicle | |

| (11) Main pump set | Type AY24, 110V motor, driving 23 000 g.p.h. jacket water pump and 1500 g.p.h. lubricating oil pump. |

| (12) Lubrication cooling water pump set | Type AY144, 110V motor, driving 7500 g.p.h. lubricating oil-cooling water pump and crankcase exhauster fan. |

| (13) Air filters | Airmaze P5 oil-wetted metallic type. |

| (14) Vacuum exhausters | Two Type AY22A6, 110V motor-driven, Westinghouse 4V110G arranged for 600 and 1200 r.p.m. with provision for the normal speed of 600 to be raised to 750 r.p.m. |

| Engine-generator-compressor set (dry) | 21.6 tons |

| Traction motor and pinion | 2.19 tons |

| Traction-heating boiler (dry) | 1.55 tons |

| Radiator fan and motor | 518 lb |

| Battery (wet-each three-cell unit) | 102 lb |

| Exhauster and motor | 798 lb |

| Traction motor blower fan and motor | 246 lb |

| Motor-driven main water and oil pump set | 588 lb |

| Motor-driven lubrication oil-cooling water pump set | 198 lb |

| Motor-driven fuel transfer pump set | 116 lb |

Locomotive Data & Performance

Description

Driver's Controls, Instruments and Gauges

Driving Instructions

Special Instructions

Boiler Operation

General Maintenance & Lubrication Schedules